Do not install radiant barrier incorrectly! Home Depot sells , APS, Arizona Public Service and Salt River Project don't support it,SRP, attic insulation, radient barrier, radiant barrier for attic, inergy systems, inergysystems.com, inergy systems, SP 3000, load controller, Pensar load controller, APS load controller, demand controller, inergy systems SP 3000, Electrosem, what is a load controller?, combined advantage rate, PV solar, solar systems, solar hot water,

Solar PV on my roof, "how much is solar" or "solar Arizona, Tempe solar, Phoenix solar and don't forget PV Solar residential.

PROPRIETARY PATENTED SUSTAINABLE BUILDING PRODUCTS

A study of heat movement, home insulation

and radiant barriers in homes

Horizon Energy Systems

Copyright 1994/2021

By: Brad Lindsay

Copyright 1994-2021

ARE WE LIVING IN OVENS?

Homes in hot climates are unknowingly designed and built to act as Dutch ovens, baking the people living in them. Homes built in hot climates using today's building standards are collecting, storing, and, unfortunately, re-emitting heat energy, long after the sun goes down and in many homes, until the next day.

Not only is this phenomenon of heat re-emission expensive for the home owner because of the costs for cooling a home, it's also uncomfortable and shortens the life of the HVAC equipment.

The re-emission of heat energy can be easily experienced by entering an attic at 11:00 p.m. after a hot day. Even though the sun has been down for several hours and the ambient temperature is under 100 F, the attic temperature is still above 125F. What is the source of this mystery heat? Hot air trapped in the attic? There is not enough volume or mass in air alone to store this many BTU's for so long. The roof? Tracking roof temperature with an infrared camera shows the roof matching outdoor ambient temperature 20 minutes after the sun goes down. Placing a thermometer into the insulation will reveal the source…stored heat in the insulation. Since the purpose of insulation is to slow heat movement, it takes hours for heat to escape once the insulation gets hot. It is very important to keep the insulation as cool as possible during the hot summer months in a hot environment. Cooler insulation means cooler ceiling. Cooler ceiling means less stress on the AC and more comfort. Remember, the "R" in R Factor stands for resistance and that's exaclty what it does all night. Heat always moves from a higher temperature to a lower temperture (basic rule of thermodynamics) so all night long the stored solar heat from the day before moves into the cooling living area all night.

WHY ARE HOMES BUILT THIS WAY?

Two reasons: First, when fossil fuels were cheap and seemingly endless, generating electricity was inexpensive. This fostered low monthly electric bills and minimal interest in energy conservation as the ROI was decades aways. Homes were built accordingly. Recent energy audits performed on homes here in Phoenix, Arizona illustrate the chronological history of conserving energy or lack thereof. Many homes built in the 40's had little or no insulation in the walls or ceiling.

Second, insulation levels used in today's homes began in cold climates where heat moves upward and is lost mostly through convective and conductive losses through the ceiling. A layer of insulation in the attic resist (R factor) these heat losses and saves energy. The term "R-factor" was then created by insulation manufacturers as a tool to gauge their new product. "The higher the R factor, the more you save" is what we were told to believe and in a cold climate this is an accurate model for savings and comfort.

Driven by rising energy costs year after year, we began to look for ways to conserve. A higher R-factor seemed to be the answer since it worked in cold climates for heat loss. The standard in the 80's was R-19 in the attic and R-11 in the walls. It was then recommended to increase the walls to R-19 by using a 6” wall stud and R-30 in the attics. The “more insulation is better” train of thought continues today as some home builders are now offering R-60 in the attic. This theory does not work in hot climates were heat becomes trapped inside insulation all. night.

INSULATION IN HOT CLIMATES

Does fibrous insulation work for radiant heat? To some extent. However, during the hottest part of the day, it can be confirmed that it is 10 to 30 degrees hotter 1" below the surface than the hottest air in the attic! What does this mean? Several inches above your ceiling is a heat layer hotter than your attic! Only infrared heat allows heat to move downward from the hot roof.

INSULATION IN COLD CLIMATES

Insulation was originally designed to minimize energy wasting conductive and convective heat losses through walls and ceilings. But what about radiant heat? Again, placing a reflective surface in the path of heat in ANY direction will reduce the need for heating OR cooling. Our Thermal Control Membrane (Space Quilt) installed over conventional insulation will change the direction of the heat leaving the building, warm the ceilings, increase comfort and lower energy costs.

COMMON BELIEFS

The sun heats the roof, the roof heats the air in the attic, which, left unchecked, will move into the home. Insulation having an R-factor or resistance to heat flow sounds like a pretty good idea when placed just above the area being cooled…or is it? What about the radiant heat being emitted from the plywood roof deck? Does insulation slow radiant heat? To some degree. But not as well as a reflective surface as we will see.

REALITY

If insulation absorbs radiant heat and is hotter than the attic air, what then is an appropriate method for reducing this commonly overlooked form of heat gain? A reflective surface with a low emissivity placed between the source of radiant heat and the area to be cooled seems like a good idea. This reflective building product is now recognized as a Radiant Barrier System (RBS). RBS placed correctly in a home can significantly reduce heat movement and increase the overall efficiency and comfort. But ten years of research has proven that RBS placed incorrectly can increase the energy consumption. Refer to fig 1 below.

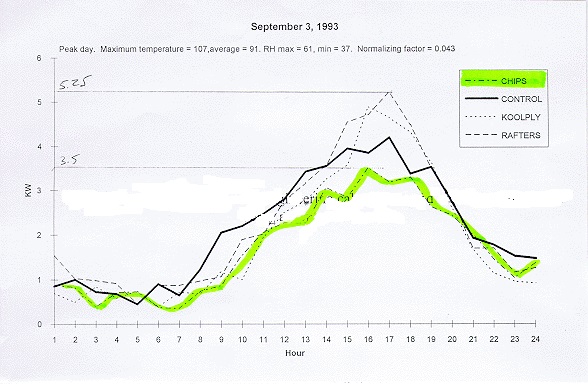

Figure 1

RADIANT BARRIER TESTING

Figure 1 illustrates the results from testing Radiant Barrier Systems (RBS), on four identical, unoccupied homes. The black line is the control home without a RBS. The other lines track three different types and placements of RBS in a residential home. The graph is based on energy consumption across a 24 hour period on four identical, unoccupied homes. Further, all homes were tested to have equal duct losses and infiltration factors by the Arizona Department of Commerce Energy Office by using a blower door and energy audits.

RAFTER RBS

This home has the RBS stapled between the roof rafters, up against the bottom of the plywood roofing material or the roof deck. This seems like a logical placement for the RBS as the roof is the source the incoming radiant heat. An obvious drawback to this design is the difficulty in trying to install it. Cramped quarters, wasted, ripped material and the potential over time for gravity to pull it down are a few problems. More importantly is the effect the rafter RBS had on energy consumption. Not only is this configuration difficult to install, it caused the home to consume more energy than the control home without a RBS.

PLYWOOD LAMINATED WITH RBS

This RBS (Was called "Koolply" but also sold as "Techshield") is applied (laminated) to the roof decking material prior to the construction of the home. No additional labor is required for installation as the RBS is in place as the roof is being nailed down. This is an obvious benefit from an installation point of view. However, like the rafter RBS, laminated plywood RBS caused this home to consume more energy than the control house without a RBS. How is this possible? The bottom surface of the wood roof deck has an emissivty of .95 which is lowered to closer to .17 after having the foil laminated to the underside thus reducing the emission of infrared heat. I will explain this in greater detail further down this page...

RBS CHIPS

Radiant Barrier Chips are a flexible, metalized film product which were cut into small, 1" squares. These reflective chips were then blown attic from a hose, much like fibrous insulation, where they form a protective shield several layers deep against the incoming infrared heat source generated by the hot roof deck. The RBS Chip was the only RBS to illustrate an energy savings over all the other homes tested. We have since improved upon the chip product with "Space Quilt".

UNDERSTANDING EMISSIVITY

In order to understand the chart above, an understanding of emissivity is necessary. Emissivity is the ability for an object to release radiant heat. The lower the emissivity, the more difficult it is for heat to leave its’ surface. This is why a chrome auto bumper is hotter than one painted black left to sit several hours in the sun.

Most paints emit in the .90 range which is very high. (See Fig 1.2) Chrome has an "E" value of .05. It will take the chrome bumper longer to get hot due the high reflectivity value, but the low emissivity of chrome traps the heat making it much hotter than the black one. Another example is leaving your toolbox open to the sun while doing car repairs. Ever try to pick up a chrome socket or ratchet handle? How about a chrome car door handle or chrome ignition starter on the steering column. The low E value of chrome prevents the absorbed heat from escaping making them very hot. This is why black chrome solar panels provide hotter water than panels painted flat black. Black chrome will take a little longer to get hot, but once it does, the low E selective surface traps heat in the absorber which in turn transfers it through conduction into the water passages. Fig. 1.2 lists the emissivity of various substrates and building materials.

Emissivity explained in layman's terms

Webster's definition:

Main Entry: emis·siv·i·ty

Pronunciation: "e-m-i si-v-i tee

Function: noun

Inflected Form(s): plural -ties

Date: 1880

: the relative power of a surface to emit heat by radiation : the ratio of

the radiant energy emitted by a surface to that emitted by a blackbody

at the same temperature

Main Entry: black·body

Pronunciation: 'blak-'bä-dE

Function: noun

Date: 1710

: an ideal body or surface that completely absorbs all radiant energy

falling upon it with no reflection and that radiates at all frequencies with

a spectral energy distribution dependent on its absolute temperature

In Layman's terms: Emissivity is the ability for radiant heat to leave the surface of an object. It matters not what the density,

mass or thickness of the object, only the surface. As can be seen below, emissivity (E factor), plays a significant role in how

heat moves into or out of our homes, our cars and our bodies.

Fig 1.2 EMISSIVITY OF VARIOUS COMMON MATERIALS

Material Emissivity value

Gold, polished .03

TCM Space Quilt .04

Silver, polished .04

Chrome .05

Aluminum, polished .04

oxidized .78

Brass, polished .04

oxidized .61

Iron, polished .21

oxidized .69

Copper, polished .05

oxidized .78

Human skin .98

EMISSIVITY OF BUILDING MATERIALS

Wood .95

Glass .94

Paint, average of 16 colors .94

Brick, common red .93

Concrete .92

Plaster, rough coat .91

SUMMARY OF PERFORMANCE

Using Fig 1.2 as a reference, lets get back to the different RBS applications and see how the emissivity affects energy consumption.

RAFTERS

The RBS stapled to the rafter reflects the incoming infrared (IR) back to the surface of the roof. This in turn heats the roof hotter than it would have been without the RBS. Is this hotter roof going to be heating the air trapped between the hot roof and the single layer of reinforeced foil? Basic thermodynamic principles confirm this.

Is this hotter membrane going to be in direct contact with the attic air? Physics confirms this

When air is in direct contact with a hotter surface will this increase the rate of convection (speed) and temperature of the attic air? Basic thermodynamic principles confirm this.

Won't this hotter air make the insulation hotter in the attic? Again, basic thermodynamic principles confirm this.

Now the heat source is removed (the sun goes down). Is the temperature of the insulation hotter than it would have been without the radiant barrier? Not necessisarily. Without any protection from a hot roof with a high emissivity surface the top 1" of any insulation product is the hottest spot in the attic. The problem lies in what happens after the sun goes down and the roof cools off?

Without a membrane the hot insulation is "seeing" that cooler roof and radiating heat towards it all night.

If there is a reflective membrane facing the hot insulation you've basically created a solar air furnace with a massive thermal storage system installed 12" deep on top of the conditioned space.

As the sun moves towards the horizon, it becomes apparent in Fig.1 that the heat is trapped inside attic, raising the demand for electricity. The RBS is reflecting this heat back into the home instead of allowing it to escape through the roof. This is not a recommended placement for a RBS. The increased roof temperature degrades any and all bitument based roofing components such as roll roofing, tar paper, shingles and laminated wood products.

LAMINATED PLYWOOD RBS (Koolply)

Since the emissivity of the plywood has been reduced by the RBS laminate, the heat is trapped in the plywood roof deck much like the chrome bumper discussed earlier. This increased roof temperature has the same effect as the rafter RBS in that it increases the temperature of the air in the attic. Similar to the rafter RBS, this application also traps the heat in the attic much like a thermos bottle keeps coffee hot; by reflecting the IR back to the source, which at the end of a day in the desert, is the attic insulation. And the higher the R-factor of the insulation, the greater potential to retain it.

RADIANT BARRIER CHIPS

The RBS Chip product was installed directly over the attic insulation offering an effective shield from radiant heat. Since the emissivity of the roof has not been lowered, heat in the attic can move back through the roof at the end of the day thereby minimizing the thermos bottle effect seen in Fig 1. Placing an RBS directly over the insulation was the original application years ago when Radiant Barriers gained attention as a viable energy source. It soon became apparent that airborne particulates such as dust would settle on the RBS thereby reducing the reflectivity and subsequently losing thermal performance. The RBS Chip product overcomes this performance degradation problem by having many layers of RBS stacked upon each other. Dust will settle on the top layers which protect the layers below. Testing by the Florida Solar Energy Center (FSEC) in 1989 showed a 42% reduction in heat flux over a test cell without a RBS and an R-factor of 19. Since then, Horizon Energy Systems, manufacturer of the RBS Chips, has done field testing in homes in Nevada, California, Michigan, Arizona and Mexico. Recently, the RBS Chip has been redesigned (a new shape and size) which is even more efficient, installs easier and offers better coverage .

DESERT TESTING

Our first full size test home was built without insulation in the attic, only two layers of RBS, one stapled up to the rafters and one layer on the attic floor where the insulation. The RBS was a highly metalized film product with a tested emissivity of .05. An identical home was built next door as a control house for comparative analysis.

Dr. Byard Wood at Arizona State University wired these homes with a 15 point pyrometer which measured temperatures in the attic, roof, interior, walls, ducts, ceiling, insulation and ambient. As the summer pressed on, the RBS home began to take the lead with regard to energy savings. This despite the large difference in electrical consumption directly related to the family of seven occupying the RBS home while the control home was occupied by a couple that both worked during the day and turned the thermostat up to 85 degrees when they left.

The most significant data retrieved from this analysis was the observation of the lack of heat in the RBS attic area, and the length of time heat was “trapped” in the control home. During the day, the RBS homes’ attic never exceeded 4 F above the ambient. If it was 110 F outside, the RBS attic was 114 F. The control house next door with R-30 blown fiberglass exceeded 145 F on several occasions. More important to note is the length of time the control home had accelerated attic temperatures (above ambient).

The ability for insulation to store heat and increase attic temperatures became apparent once again as it was decided to add conventional insulation to the RBS homes’ attic for sound and winter months. The insulation truck arrived at 9:00am. By noon, a 3” layer of blown cellulose (R-19) was added above the RBS already laid out on the attic floor completely covering it. By 2:00 the attic was hotter than it had ever been. Subsequent testing on other homes illustrated similar data: the insulation was hotter than the attic air.

Insulation in hot climates when subjected to infrared heat in the attic and walls has the capacity to store a tremendous amount of heat for many hours...millions of BTU's over the course of a summer. We are working to change outdated and archaic building codes that are not climate specific.

CONCLUSION

Twenty one years of research, intensive thermographic scanning and exhaustive documentation have led to some surprising results: The attics of our homes are in reality low-heat Dutch ovens, costing millions in energy costs and reducing interior comfort. The bottom line? Protect insulation from the intense radiant energy emitted from the roof deck with a RBS installed in the correct place. This in turn reduces convective and conductive heat transfer. Keep the insulation cooler and you reduce the energy required for cooling increase interior comfort and extend the life of the most expensive appliances in your home: furnaces and A/C units.

It can be seen that a quality Radiant Barrier System has a place in every home to reduce energy costs and increase interior comfort. Recent installations in cold climates have shown significant reductions in heat loss saving energy and increasing interior comfort. Why wouldn't it? Consider a thermos bottle which works equally well for hot coffee or ice tea.

It must be recognized that an alternative form of measuring the performance of insulation is necessary as the "more insulation is better" mind set does not necessarily mean better thermal performance.

Additional information on RBS and heat movement can be seen on the internet at our web site: http://www.savenrg.com

RBS Chips in a residential attic

Lifetime, transferable performance warranty

News Update:

Tim Carter, nationally known syndicated columnist and web

master for www.askthebuilder.com, has had our in

his home for over two decades. He has experienced what our

products can do during hot summer months and cold winters of

Cincinnati. Hear what he has to say about it: click here

Thermal Control Membrane (26" wide), installed between scissor trusses. TCM is also available in 48" wide rolls

Dust proof, simple to install, lasts forever, immediate difference in comfort. Unconditional money back guarantee.

Web page design and maintained by B Rad Design Group

Copyright 1997-2021 all images, text and HTML copyrighted by Horizon Energy Systems.

All rights reserved and violators will be prosecuted.

Information in this document is subject to change without notice.

Other products and companies referred to herein are

trademarks or registered trademarks of their

respective companies or mark holders.