This page

contains information regarding the negative effects of dust on radiant

barriers. The following tests were not performed by a government agency,

approved testing facility or NASA. A 24" square infrared heating panel was

used as a background source of heat with an emissivity of .95 and a measured

surface temperature ranging between 192f to 210f. Temperatures shown in

the images below were taken with a Raytek IR surface reader and IR images using

Cincinnati calibrated infrared camera. Recorded using a Sony PC-105

dv. Draw your own conclusions from the information presented

below.

Controlled conditions surrounding this test:

Inside dry bulb air temperature: Maintained at 86F + - 1.5F

Emissivity of inside surfaces of test cell: .95

Surface temperature of cell: (sheet rock) 80F

Camera distance: 17'

Lens: 36mm

Shown here is a foil/paper/foil

laminate

removed from an attic. The clean and

reflective sides clearly indicate where the

overlapping pieces protected the surface

below as it still reflective. The 12 years of dust in the center is what this test is

focused on.

This is the logic behind the patent on our

Thermal Control Membrane and Radiant

Barrier Chips. The top surfaces are

sacrificial to the layers below which, since

they are 8 to 10 layers deep, will always

remain reflective.

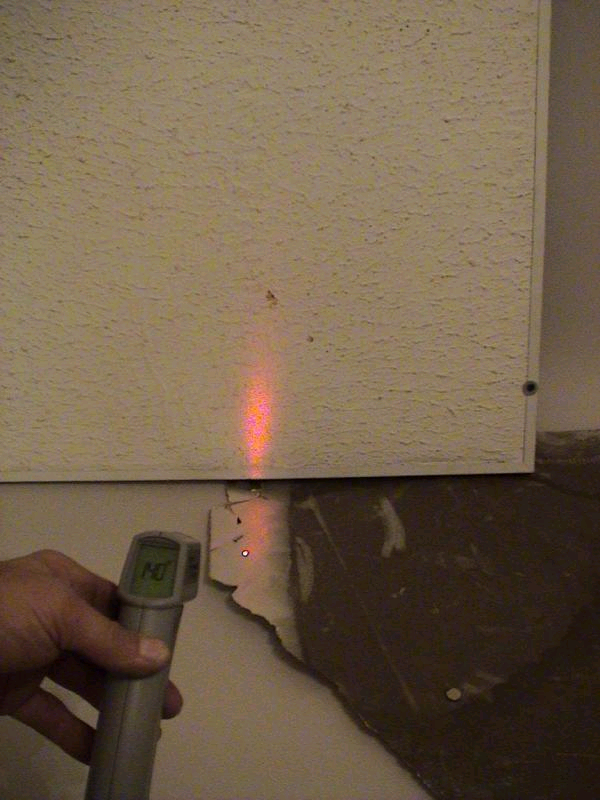

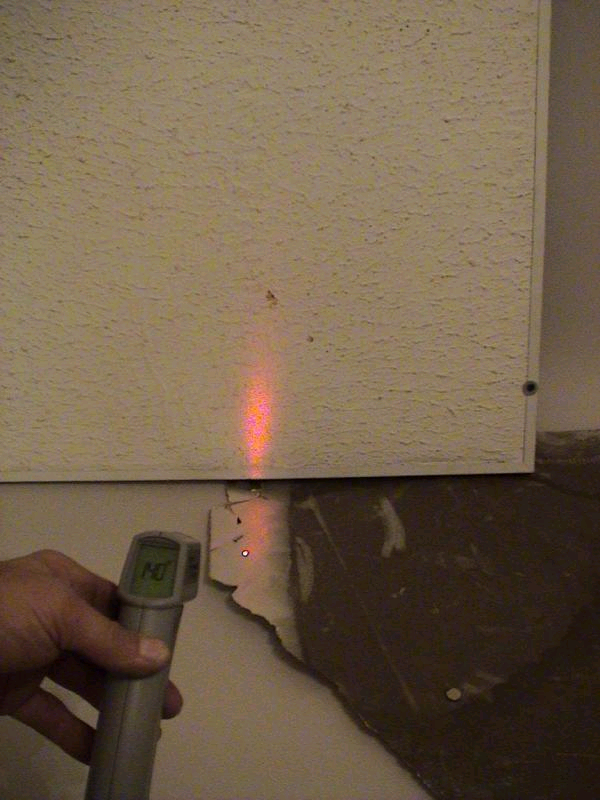

This infrared heating panel maintains a constant surface temperature and shows 192F here.

The thermometer is reading 140F as this is what it "sees" bouncing off the reflective edge of the radiant barrier sheet.

Notice the red laser on on the heating panel? This shows visibly the same path infra red heat is taking to be read by the gun which is not aimed at the hot surface.

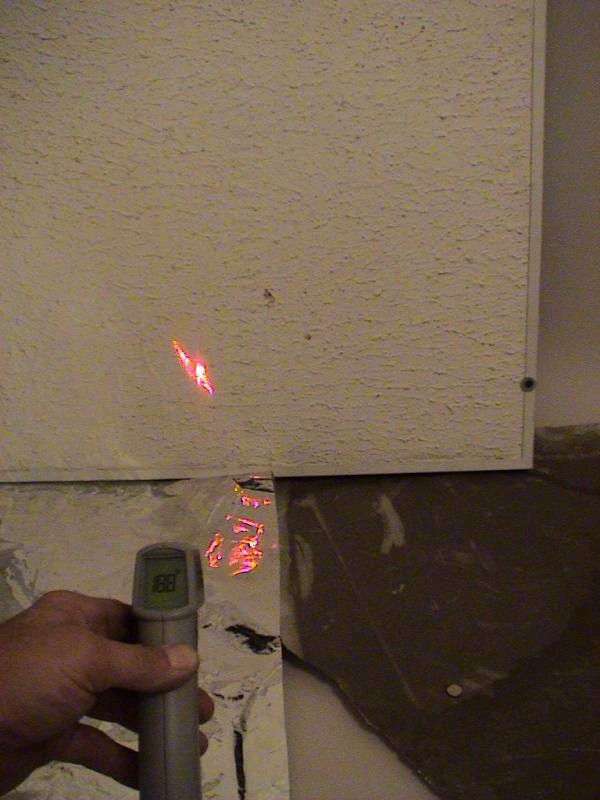

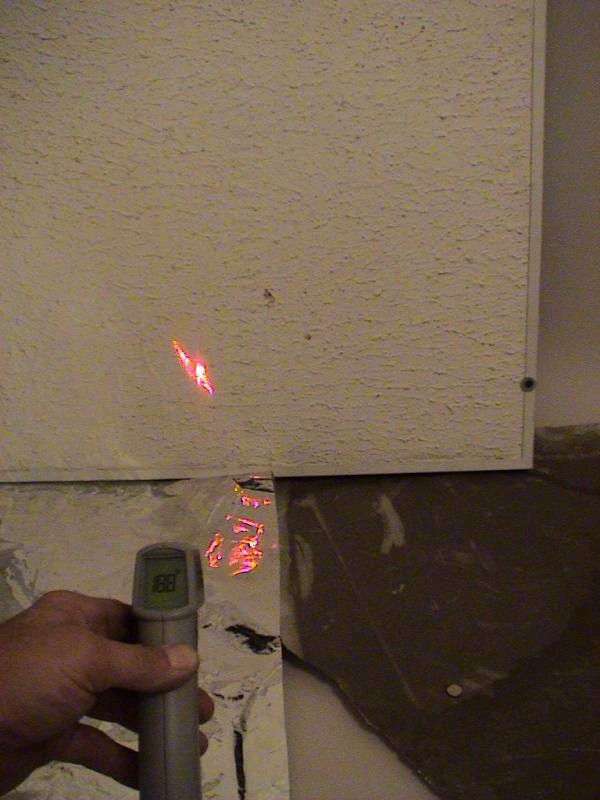

With the reflection gone from dust build up it is evident that infrared heat is no longer being bounced off of it. Either is the laser beam.

The gun reads 86F.

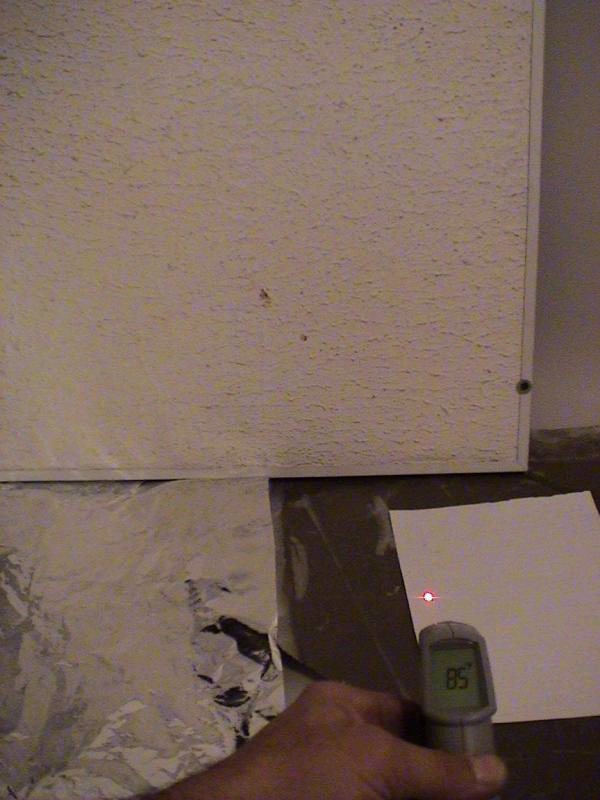

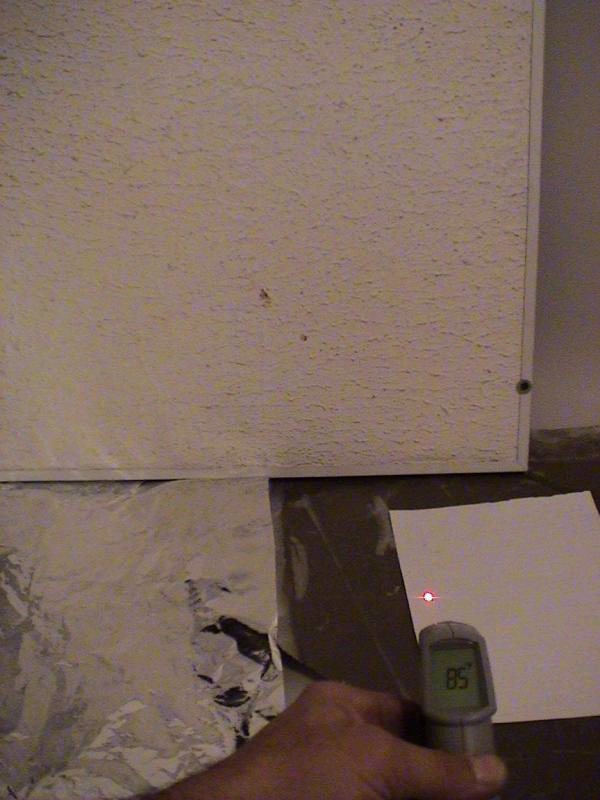

Here is a comparison of the dusty radiant barrier compared to a piece of copy paper with a measured emissivity of .95.

Paper has very little reflective value and as can be seen nor does dusty radiant barrier.

That's all we've got for now, stay tuned for more exciting information regarding this issue.

Ask us how to install RBS Chips yourself click here

Thermal Control Membrane click here

Our Lifetime Performance Warranty: click here

Controlled conditions surrounding this test:

Inside dry bulb air temperature: Maintained at 86F + - 1.5F

Emissivity of inside surfaces of test cell: .95

Surface temperature of cell: (sheet rock) 80F

Camera distance: 17'

Lens: 36mm

removed from an attic. The clean and

reflective sides clearly indicate where the

overlapping pieces protected the surface

below as it still reflective. The 12 years of dust in the center is what this test is

focused on.

This is the logic behind the patent on our

Thermal Control Membrane and Radiant

Barrier Chips. The top surfaces are

sacrificial to the layers below which, since

they are 8 to 10 layers deep, will always

remain reflective.

This infrared heating panel maintains a constant surface temperature and shows 192F here.

The thermometer is reading 140F as this is what it "sees" bouncing off the reflective edge of the radiant barrier sheet.

Notice the red laser on on the heating panel? This shows visibly the same path infra red heat is taking to be read by the gun which is not aimed at the hot surface.

With the reflection gone from dust build up it is evident that infrared heat is no longer being bounced off of it. Either is the laser beam.

The gun reads 86F.

PROVEN

PERFORMANCE

This illustrates the reflective power of our

reflective insulation products. The more

reflective the surface the easier heat will

bounce off it and inhibit the emitance of

heat on the bottom side. This is called

"emissivity" and is a measurement given for

the ability for a surface to radiate heat.

Our products have been tested by Oak Ridge National Laboratory and have a

measured

emissivity of .035, the lowest in the industry.

What really sets our products apart is the

space between the layers of these surfaces

stacked on top of each other.

Blown in squares called "RBS Chips" or our

latest product line: "Thermal Control

Membrane"

The gun is reading nine degrees less than the 197F shown in the first picture. Scroll up to see how well the reflective edge of the foil material does.

This illustrates the reflective power of our

reflective insulation products. The more

reflective the surface the easier heat will

bounce off it and inhibit the emitance of

heat on the bottom side. This is called

"emissivity" and is a measurement given for

the ability for a surface to radiate heat.

Our products have been tested by Oak Ridge National Laboratory and have a

measured

emissivity of .035, the lowest in the industry.

What really sets our products apart is the

space between the layers of these surfaces

stacked on top of each other.

Blown in squares called "RBS Chips" or our

latest product line: "Thermal Control

Membrane"

The gun is reading nine degrees less than the 197F shown in the first picture. Scroll up to see how well the reflective edge of the foil material does.

Here is a comparison of the dusty radiant barrier compared to a piece of copy paper with a measured emissivity of .95.

Paper has very little reflective value and as can be seen nor does dusty radiant barrier.

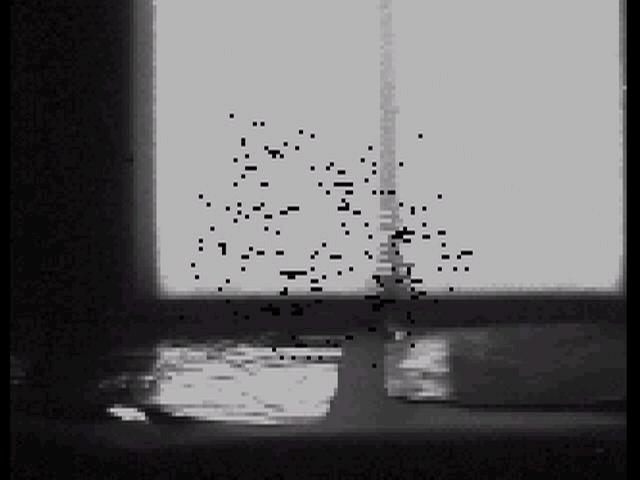

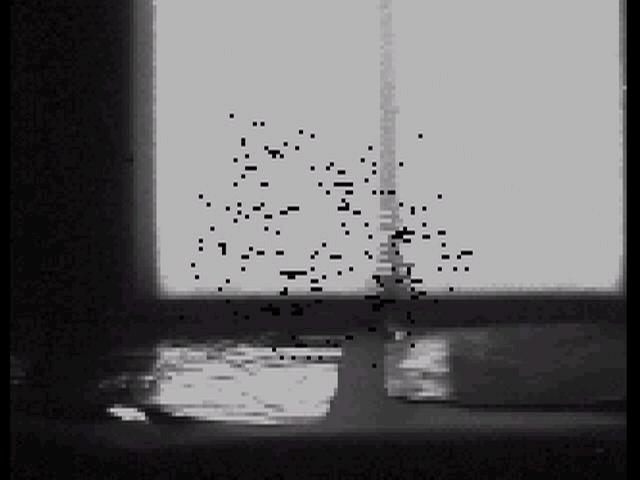

This is an infra red image

in gray scale showing the amount of heat being reflected by our RBS Wrap (on the

left), the reflective strip on the edge of the dusty radiant barrier and the

center of the dusty sheet.

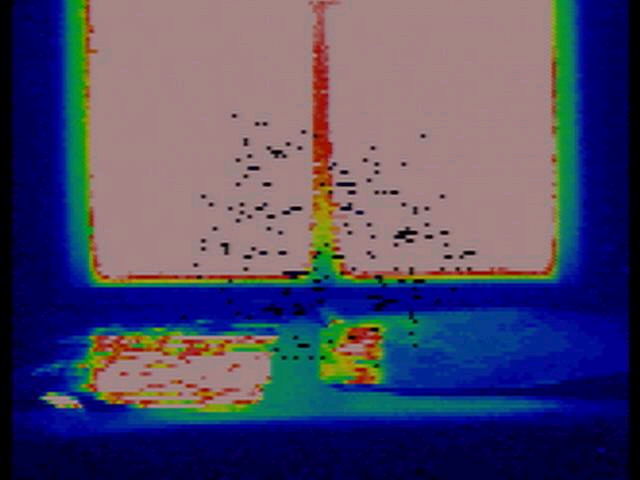

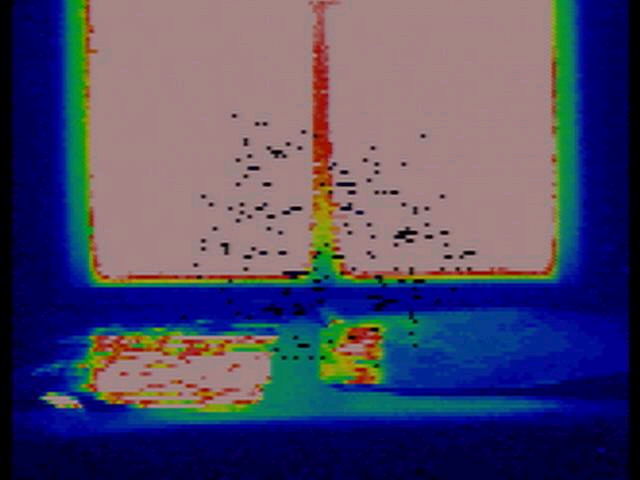

Same image in color scale. Notice the dusty radiant barrier is almost the

same temperature as the walls behind it. Even the flat paper between the

RBS Wrap and the dusty radiant barrier has more reflective qualities than the

dusty radiant barrier on the right.

That's all we've got for now, stay tuned for more exciting information regarding this issue.

Ask us how to install RBS Chips yourself click here

Thermal Control Membrane click here

Our Lifetime Performance Warranty: click here